Inspection of lifting lugs

- Lifting Lug Design Handbook Pdf

- Lifting Lug Design Manual

- Lifting Lug Design Handbook

- Lifting Lug Design Manual Pdf

Litfing lugs -or trunnions- in pressure vessel shall comply with ASME BTH-1 Design of Below-the-Hook Lifting Devices, where the nominal design factor Nd= 2 (min.) for category A. Regards RE: Does design of lifting lug have some standard practice? At all lifting positions forces acting on lifting and tailing lugs are calculated as given below and maximum of acting force is taken for the analysis. Lifting lug forces: Maximum transverse load per lug P T = P cosθ / N. Maximum longitudinal load per lug P L = P sinθ / N. Where, N = number of lugs. Tailing lug forces.

Tuesday, 1 October 2019

Basic Lifting Lug Categories

It may be a surprise to learn that lifting lugs are not ‘all the same thing’. First of all, we can clarify the situation by dividing our ‘lifting lugs’ into three groups:

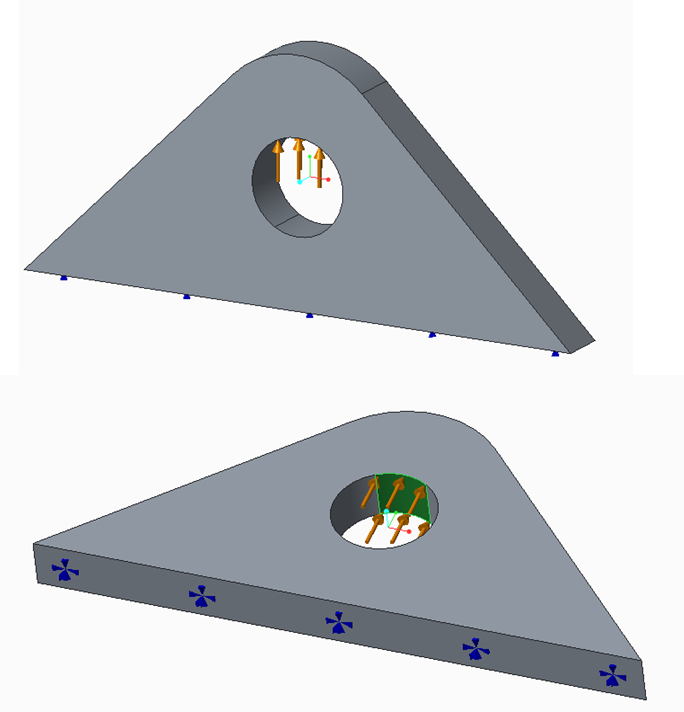

Diagram of lifting in relation to lifting lug category

All of these lugs have some things in common, we need them to be:

- Properly identified as a lifting point.

- Have a load rating.

- Be compatible with standards compliant lifting gear.

Australian Standards and Lifting Lugs

Of the three types of lug, the first two should be relatively straight-forward from a Standards perspective.

A lug up high inside a building, pointing down is a classic ‘fixed lug’

The “fixed lug” is something that is philosophically no different to a simple crane, and accordingly we should expect that a crane standard like AS1418 must be applied to it.

Fortunately for the “lifting device lug” it is also usually very clear what standard applies to lifting tackle and lifting devices. AS4991 is often the best fit.

AS4991 Lifting Device, unsurprisingly equipped with a lifting lug

Some might say that payload lugs are ‘another kettle of fish’ altogether. This is not true.

Payload lugs suffer all of the demands of load dynamics and sling compatibility that apply to lifting devices.

From a structural and functional perspective the only difference from a “lifting device lug” is that potentially a low duty cycle (in terms of number of lifts) might apply. In all other respects the minimum strength and manufacturing risk controls of AS4991 or an equivalent standard should apply.

Accordingly, we place these lugs under AS4991-2004 and other lifting tackle standards also.

This sort of discussion does not begin to address the complexities of the lugs themselves.

A typical industrial landscape, with apparent payload (lifting) lugs

Lugs can and do come with a wide variety of shapes and sizes. At any given site there might also be thousands of them, and it can become overwhelming.

Periodic Inspection

For site managers and engineers, the advice is clear. Treat your payload lugs like any other piece of lifting equipment.

- If they are for continuing use, they should have a periodic inspection regime applied and managed with a suitable register.

- At all times they should be competently assessed to have sufficient strength for use, or if not – their use should be forbidden.

- Payload lugs which are authorised for use must be clearly identified as such.

- A risk assessment should consider the risk controls applied to lifting gear and the appropriate practicable risk controls applied to the payload lugs.

We must also say that payload lifting lug inspection in general is a specialised task. It relies on sufficient competence and experience to be able to discriminate between the condition and status of lugs without definitive reference dimensions.

Pre-use Inspection

Lifting Lug Design Handbook Pdf

There are two parts to lifting gear inspection. There is periodic inspection – and there is pre-use inspection.

Presenting end users with a massive diversity of lifting lugs, particularly payload lugs can leave them feeling powerless and not in a position to do what everyone must do before every lift – and that is to inspect the lifting gear…. A pre-use inspection.

Let’s ask then - “What pre-use checks can anyone make?”

What can we all look for?... Well here is a list of suggestions:

- A Lifting lug must be properly identified as a lifting point. If we lift from just any piece of steelwork with a hole in it, we might be lucky – and that is not something we can rely upon.

- A lifting lug must have a load rating. This might not be sensible to mark upon the lug itself, but we must always have a clear idea of what rating our lug ought to have.

- Check lugs made from steel plate using a shackle. It’s obvious if you think about it. Common lifting shackles (like our AS2741 grade S type) have been used all over the world for decades to lift things with steel plate lifting lugs. It’s logical that one and the other should fit together reasonably well. If we know what size the shackle we should be using is – then we can compare this with the lug. If the lug has a hole that seems too small, or if the lug is radically thinner than the width of the shackle mouth, or if somehow it ‘just doesn’t seem to have enough steel in it’ – then this should prompt questions and assurance must be sought.

A shackle and lug combination that clearly doesn’t work well together – is this really a properly rated lifting point?

- A Lifting lug must always have good welds. In a very real sense – there’s no excuse for bad welds. There’s certainly no place for messy looking welds associated with any lifting lug. If the welds look rough, ropey, or something amateurish then definitely don’t use the lug!

Frightful… how has this lasted long enough to gather rust? – cut it off!

- Round holes should stay round. If it’s obvious that a lug hole has worn from round to oval by more than 10% - then don’t use the lug.

Lifting Lug Design Manual

A nasty lug, but also a nasty lug with nasty shaped hole

Lifting Lug Design Handbook

Lifting Lug Design Manual Pdf

- Sharp edge wear has no place in lifting lugs. Are there burrs, dents and dings that look painful to the touch? Then this indicates excessive wear and that repair before use is probably essential.

This one has done some work, but that edge could damage a sling or generate a crack.

Nobles can provide services to help improve the safety of lifting lugs of all types: overhead crane assessment and maintenance; field technicians to inspect and maintain registers of lifting lugs; onsite load testing and NDT services; and engineering design or review of lifting lugs with reference to Australian Standards.

To speak to one of our specialist technicians about your lifting equipment or servicing, please call 1300 711 559 or send them an email at techservices@nobles.com.au.